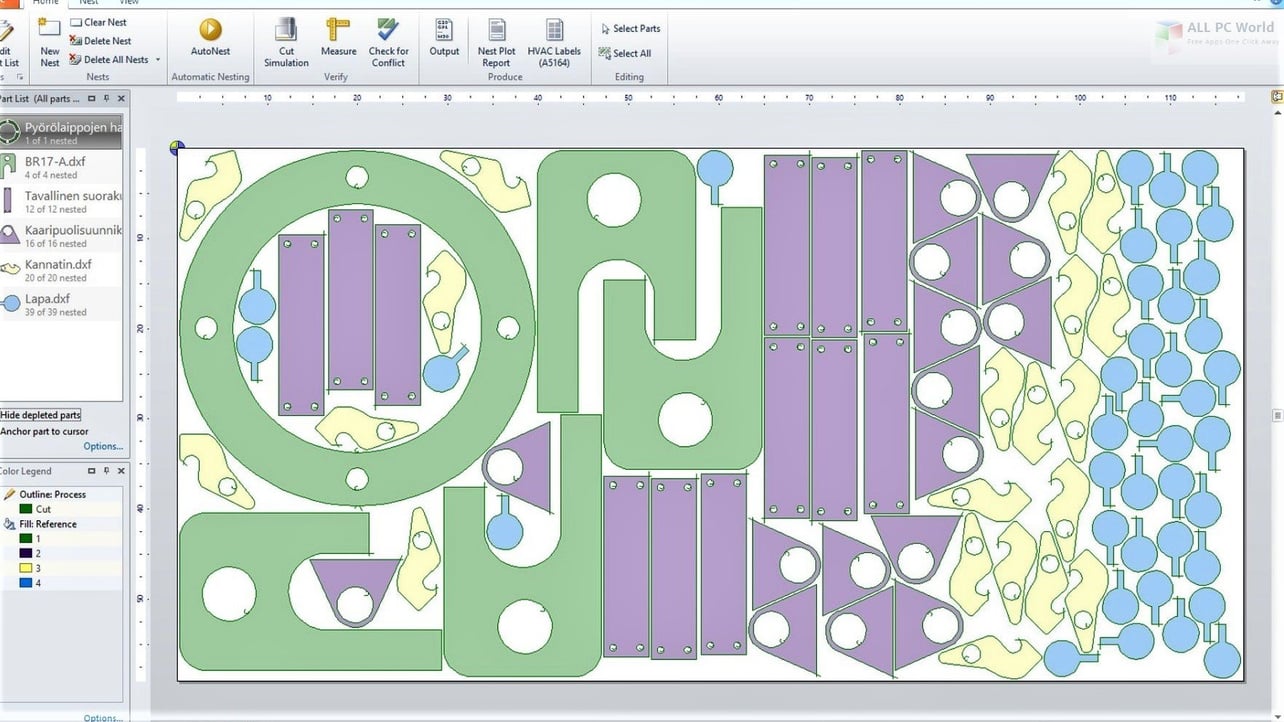

It is an integral and indispensable part of sheet metal bending operations that will not only automate and speed up the numerous repetitive calculations and drafting but also help you in achieving the same with the maximum degree of accuracy and efficiency thereby saving labor.

Free sheet metal bending program.

Therefore it is not part of the standard freecad install.

Design chassis rollcages handrails etc.

The sheet metal model built with the sheet metal add on rear.

Sheet metal design software considers the fabrication methods needed for manufacturing.

Simulate bending while displaying the part tooling gages bed and ram at each step allows the programmer to verify bending sequence and manually modify tool part and gage positions.

Sheet metal boxes are two part enclosures made by cutting metal sheets and then bending the resulting parts using a press brake to form a box.

By adding cutouts for ports switches ventilation or mounting these versatile and cost effective enclosures can be used in applications ranging from electronics to robotics.

Bend o matic is a revolutionary professional software package to determine initial unfolded length.

Sheet metal is an external workbench evolved to design and unfold sheet metal parts.

Bending radbend offline programming for press brakes full 3d simulation for sheet metal bending.

Bend tech dragon cnc and software will help you with your tube pipe fabrication process.

Create and edit part programs offline.

The flat pattern can be used to document and manufacture associatively as the design changes.

Radbend is the market leading solution in offline programming for press brakes.

Litio is a sheet metal fabrication program that calculates flat unfolded sheet development of ducts rectangle to round transitions cylinders cones pipe intersections connections.

Almacam bend is proposed with unfold alma s module for unfolding sheet metal parts from the model of the part designed in unfold or imported from an external cad software programming the press brakes can be easily managed with.

Bending is one of the most common sheet metal fabrication operations.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

In front of it the unfolded solid.

As you create flanges and add bends the sheet metal design software will accurately represent the flat pattern required.

The force must exceed the material s yield strength to achieve a plastic deformation.

The almacam bend software product can simulate the complete bending process and remotely program the leading brands of cnc press brakes in a highly automated way.

Completely integrated with radan3d along with solidworks autodesk inventor providing full 3d simulation of the bending process.